Bowman X-Ray Fluorescence XRF Plating Measurement

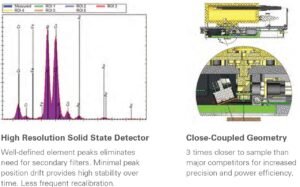

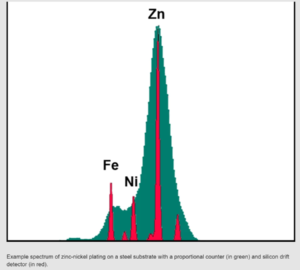

XRF instruments use X-ray fluorescence technology to determine the thickness and composition of plating deposits with exceptional accuracy. Measurement is performed by exposing a precisely defined area of the test specimen to x-ray energy. This causes X-ray emission (fluorescence) from both coating and substrate, which is detected with a high precision energy-dispersive detector. Energy resolution, detection efficiency, and robustness are three factors relative to detectors.

Elemental Analysis

Where layers of pure metals or alloys are used to enhance product features, it is important to precisely determine both coating thickness, and the elements in the sample.

Applications for elemental analysis

- Materials analysis of coatings and alloys

- Goods in inspection

- Manufacturing process control

- Trace analysis of contaminants

- Materials research & development

- Plating composition and thickness analysis for electronic components and connectors

- Analysis of PCB finishes, e.g. gold and palladium alloy coatings of ≤ 0.1μm, and nickel coatings

- Analysis of imported gold (and other PMs), jewelry and watche